Flax Management TIPs: Flax Harvest & Storage

Late Harvests:

Flax is fairly resistant to shelling out (pod shattering) and can endure poor weather conditions better than other oilseeds, such as canola. However, boll drop may occur especially in standing overripe flax fields.

If there is a risk of snow prior to harvest or if regrowth occurs in the fall, swathing may be preferred over straight cutting. Swathing will reduce the risk of boll drop, will allow bolls and stems to uniformly dry down and make it easier to combine late in the fall.

Fall rains may cause weathering of mature seed and frost may cause immature seed to turn black, which could result in grade reduction. Frost will not damage mature seed.

During years when harvest conditions are wet, as seen in many areas this year, there is a higher likelihood that flax will be harvested at higher seed moisture content. It is important to properly condition the seed to a safe moisture level prior to storage. The risk of spoilage and heating is considerably higher for tough and damp flax, compared to cereal crops.

Flax Storage:

Flax is considered dry when the seed moisture content is less than 10%. If flax is to be stored for long periods of time, the moisture content should be between 8 and 9% to reduce the risk of spoilage and heating.

Freshly harvested seed can maintain a high respiration rate for up to six weeks before it becomes dormant. Heat and moisture, which are byproducts of respiration, increase the risk of spoilage. When possible, flax seed should be cooled down to below 10°C as soon as possible after it is put into storage. Even dry flax seed is at risk of spoilage due to its high oil content. As such, flax seed should be routinely monitored for the development of hot spots, which can rapidly spread throughout the bin.

Temperature and moisture are important factors that contribute to the risk of stored grain spoilage (see figure below). It is important to note that there is no absolute line between no spoilage and spoilage. This figure represents a general description of how initial seed moisture content and initial seed temperature impact safe storage of grain.

From: Canadian Grain Commission (2013).

During storage, high moisture spots can develop through moisture migration and can occur regardless of the moisture content the seed was binned at. The development of high moisture spots usually occurs in late fall and early winter but can also happen in the spring. When this is coupled with mould growth, heating can occur.

Dockage:

- The presence of dockage can raise the moisture content of flax seeds enough to cause heating and moulding.

- When possible, dockage should be removed prior to long term storage.

Storage of Tough or Damp Flax:

Flax with 10.1-13.5% moisture is considered to be “tough”. Flax with >13.5% moisture is considered to be “damp”. With elevated moisture levels, the risk of heating and spoilage increases significantly.

When seed moisture is above the safe long term storage level (8-9%), aeration and natural air can be used to condition flax. It is important to monitor the bin for changes in moisture and temperature by sampling the top, bottom and middle of the bin separately.

When seed moisture levels are high, additional measures should be taken to reduce the risk of spoilage during storage. For example, turning or moving the seed periodically to help mix up hot/moist spots. Aeration (cooling) will result in a small reduction of seed moisture content. If the seed is very tough or wet, a grain drier may be more effective to bring the moisture content down to a safer storable level.

Achieving sufficient airflow rate is challenging with crops like flax. The size and orientation of flax seeds generate a large static pressure or resistance to airflow (i.e. dense), resulting in a lower airflow rate from fans. The old rule of thumb to have 1 horsepower of fan power for every 1000 bushels may be misleading, particularly for flax. The easiest way to reduce the static pressure (and increase airflow from fans) is to reduce the grain depth (e.g. partial filling of bins).

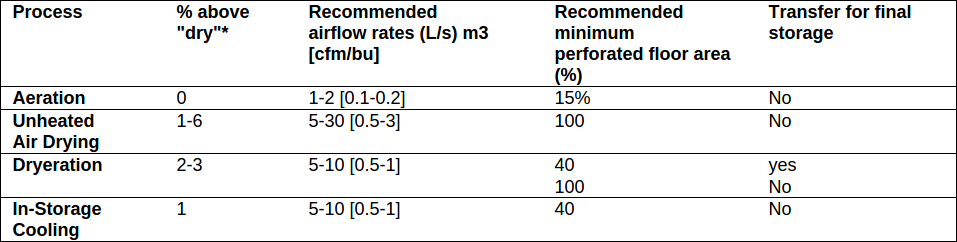

Refer to the table below for the target airflow rates required for different grain storage management practices.

From: Manitoba Agriculture, Food and Rural Development.

Quick TIPs for Safe Storage (Ron Palmer, IHARF)

- Turn the fan on as soon as the floor of the bin is covered, and run the fan until 9 AM the next morning. Do this whether the flax is tough or dry. We want to get it as cold as possible (well below 10oC) for safe storage. Research has shown that the first 24 hours is very important and typically a one percentage point drop in moisture content occurred as grain was cooled down in that first 24 hours.

- If the flax seed is still tough (greater than 10% moisture content), then follow the yard light rule, turning the fan on at 9 PM and off at 9 AM the next morning. If it is raining, or about to rain with a high relative humidity; skip that night of turning the fan on. Follow this rule until the flax is dry, i.e. less than 10% moisture content.

- To aid in the drying, a truck load could be removed to draw down and flatten the peak of grain in the bin. This would be especially useful for flax that is quite tough. Heating and spoilage typically start in the upper core of the bin.

- If the flax seed is dry, then the objective would be to keep it as safe as possible, by keeping it as cold as possible. Follow this simple rule: Turn the fan on if the outside air temperature is less than the flax temperature. Again, if it is raining or about to rain with a high relative humidity; do not turn the fan on. Low air flow of 0.1 CFM per bushel can be used, but this rule should be followed right into the dead of winter and even into spring. This will keep the flax seed as cold as possible and provide the safest storage possible even into the spring and summer of the following year.

- Seed at the bottom of a grain bin dries first and the moisture content at the bottom always ends up a couple of points below that of the top of the bin. To mitigate this discrepancy, one could load the bottom of the bin with tougher flax and save the dry flax for the top of the bin. This may work out well as morning harvest results in tougher seed and as the day progresses the flax seed is drier. Spoilage and heating often start in the central upper core of the bin and to safeguard against this it would be best to have the driest grain there.

Storage Insects:

Storage insect are not typically a major problem in flax because flax seed is not a nutritionally optimal diet for many insects. However, saw-toothed grain beetle, confused flour beetle, merchant grain beetle and red flour beetle can occur in stored flax seed. Fungus beetles and mites have also been found in seed that remained tough or damp in storage.

The activity of insects is generally retarded below 18°C. If flax seed is cool and dry, insects generally will not thrive.

Malathion should not be used for treating bins of flax and other oilseeds. Flax should not be put in bins pretreated with malathion or have malathion dust added during filling.

Additional information is available on the following websites:

Flax harvesting, please refer to the Flax Grower Guide Chapter 10 – Harvesting, which is posted on the Flax Council of Canada website.

Conditioning tips for stored canola (which has many similarities to flax) is at http://www.canolawatch.org/category/2015issue-26/

General information on Drying and Storage of Damp Grain may be found at http://www.gov.mb.ca/agriculture/crops/production/drying-and-storage-of-damp-grain.html