Flax TIPS: Getting Ready for Harvest: Late Season Insect Monitoring, Pre-Harvest Intervals, Desiccation Timing and more.

Late Season Insect Monitoring

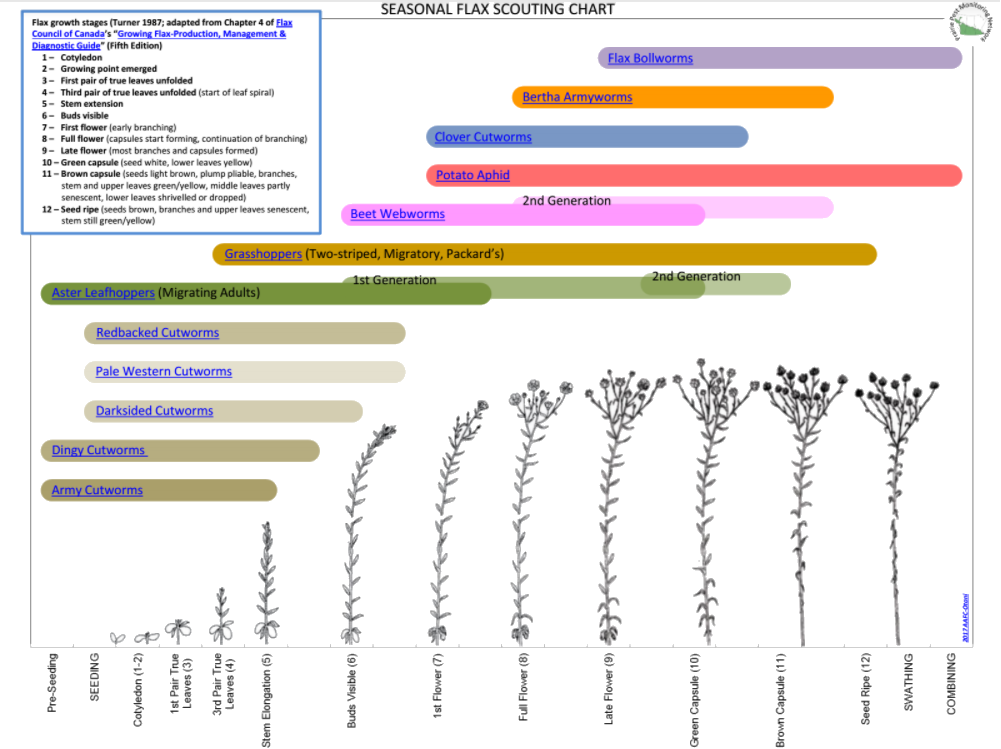

There are several insects pests, as illustrated below that can affect flax during flowering and boll formation. Scouting is important to monitor insect populations and development prior to making management decisions. Flax fields rarely see economic levels of all of these, but there are a few insects pests that are generalists and will also feed on flax when populations are high. For up-to-date maps of current pest surveillance data across Manitoba, Saskatchewan and Alberta, visit the Prairie Pest Monitoring blog

Bertha Armyworm

Bertha armyworm rarely causes economic damage in weed-free fields of flax. Bertha armyworm seems to prefer Brassicas over flax, however, if populations are high in canola or mustard crops and they have been recently swathed, larvae can move into adjacent flax fields. Bertha armyworms chew through the stems below the bolls, causing them to drop off the plant.

Economic threshold: No economic or nominal thresholds have been established for flax. If bertha armyworms are seen in flax, thresholds are likely to be lower than for canola (i.e. fewer can cause more damage).

Control: Flax fields should be monitored for bertha armyworm if populations have been high in surrounding crops, and if surrounding crops are being harvested leaving flax as the next potential food source. Insecticides are registered for control (Coragen, Volium Xpress, Lannate, Chloropyrifos).

Potato Aphid

Potato aphid commonly occurs in flax, and can cause economic yield loss. Peak densities are often reached in late July or early August, and tend to drop dramatically by mid-August as aphids return to winter hosts.

Economic threshold: >3 aphids/ plant at full bloom; 8 aphids/ plant at green boll stage.

Control: Insecticides are registered for control (Lagon/ Cygon); numerous natural predators like lady beetles, lacewings, hover fly larvae and parasitic wasps.

Grasshoppers

Grasshoppers may move to flax after other crops have been harvested and food sources become scarce. The most common species that affects flax is the twostriped grasshopper, Melanoplus bivittatus. Significant damage can occur as grasshoppers feeds on or clips off buds and bolls.

Economic threshold: We do not have economic thresholds for grasshoppers in flax, but a nominal threshold of 2 grasshoppers/ m2 should be considered if grasshoppers are clipping bolls.

Control: Managing grasshopper populations in surrounding crops and margins can help reduce populations that may migrate into flax late in the season. Harvesting as soon as the crop is ready can be advantageous to prevent further damage. Several insecticides are registered for controlling grasshoppers in flax (Coragen, Decis 5EC, Matador/Silencer, Volium Xpress, Malathion).

Aster Leafhoppers

Aster leafhoppers can carry the aster yellows phytoplasm and crinkle virus which can affect flax. It causes yellowing and abnormal flower development which leads to lack of seed set. This year, aster leafhopper populations have been low in pest surveys, and there have been no recorded positive confirmations of the virus.

Pre-harvest Intervals

Pre-harvest Interval (PHI) is the time between the last application of a pesticide and harvest. Not following PHIs increases the risk of testing above Maximum Residue Limits (MRLs) which has the potential to impact export shipments. Most exporters or grain buyers will have specific intolerances in their declaration forms upon grain purchase. ‘Harvest’ refers to the time of swathing or the time of straight-cutting. This means depending on the stage of your crop you may have a wider window if you switch from swathing to straight-cutting.

| Products Registered for Flax (Mid-Season Application) | Pre-harvest Interval |

|---|---|

| Coragen | 1 day |

| Malathion | 7 days |

| Matador/ Silencer | 7 days |

| Volium Xpress | 7 days |

| Lannate | 8 days |

| Chlorpyrifos | 21 days |

| Headline EC | 21 days |

| Lagon/ Cygon 480 EC/ Cygon 480-AG (OP) | 21 days |

| Priaxor | 21 days |

| Decis | 40 days |

Chemical Desiccation and Pre-harvest Herbicides

Desiccants and pre-harvest herbicides can be a good option to facilitate crop dry down and ease harvest. However, it is important to note that both desiccants and pre-harvest herbicides do not speed maturity. Products should be applied only after the crop has reached physiological maturity (75% brown and rattling bolls). Once dried down, the crop is at risk of boll shattering and should be combined as soon as possible after samples test 10% moisture.

If perennial weeds are a problem then glyphosate may be a good option to control weeds while also drying down the crop. This can also be beneficial to prevent green material from entering the combine. Glyphosate can also reduce plant re-growth because of the systemic mode of action of the product. Seed growers, or those planning on saving seed for the following year should not use glyphosate as it can reduce seed germination. Diquat does not cause any effects on germination.

Desiccants are generally faster acting, especially as temperatures have begun to drop which may cause reduced efficacy of glyphosate. If the plant has matured (brown bolls) but stems remain green, diquat may be advantageous since the product does not require an actively growing plant. However, benefits must be weighed against the higher costs associated with the product.

| Product | Glyphosate | Diquat |

|---|---|---|

| What is it? | Pre-harvest herbicide | Desiccant |

| Mode of Action | Systemic | Contact |

| Effects of Growing Conditions | Best results when plants/weeds are actively growing and daytime temperatures are around 20°C. | Best results when conditions are cloudy or in the evening. |

| Application Timing | 75% brown bolls | 75% brown bolls |

| Pre-harvest Interval | 7 to 14 days (Under ideal conditions) | When sample tests dry |

| Pros and Cons |

|

|

NOTE: BASF’s Heat (Saflufenacil) does NOT have established MRLs. Use on flax is not recommended. MRLs are predicted to be in place for the 2018 harvest season.

Swath or straight-cut?

There are a number of factors to consider when selecting management practices for harvesting flax. The following is an overview of the benefits, challenges and ways to optimize harvesting flax.

Straight-Cutting

Flax is well suited to straight-cutting due to low shattering risk (relative to canola) and seed bolls that develop high up on the plant. However, flax does cause some unique challenges due to the tough, fibrous nature of the straw. Cutter bars should be well maintained and sharp to prevent gumming up of the knife. Desiccation can be an alternative to waiting for natural dry down, such as when moist soil conditions result in stems staying green, or a hard killing frost. Straight-cutting should occur when mature seed is 10% or less seed moisture content, which is generally around 95-100% brown boll stage.

Swathing

Swathing of flax has become less common, largely due to larger farm size and the availability of improved equipment which facilitates straight cutting, reduces labour and harvest time. However, swathing can still provide advantages over straight-cutting in some years. For example, swathing can be a good alternative to straight cutting if re-growth occurs in fall, such as when desiccation has not be used, there is a wet fall after a dry August or a lack of killing frost. Swathing should occur when bolls are 75 – 80 % brown (mature crop). Cutting prior to this stage can result in seed weathering, and reduced seed weights. Immature seeds can be damaged by frost at -3°C to -5°C range. To ensure drying and prevent movement by strong winds, stubble height should be 4 – 6 inches and rolling swaths is recommended.

| Straight Cutting | Swathing |

|---|---|

| Straight-cutting should occur when mature seed is 10% or less seed moisture content | Swath when bolls are 75 – 80 % brown (mature crop) |

| No risk of loss from flax rolling with strong fall winds | Good alternative to straight cutting if re-growth occurs |

| Facilitated by pre-harvest herbicides and desiccants | Maintain a stubble height of 4 to 6 inches |

| Maintain sharp knives on cutter bars to prevent gumming. Can cause wearing of equipment. | Roll swaths to prevent from rolling in high winds |

Long-term Storage

Flax can be a difficult crop to market as movement to bulk export markets generally takes place only a couple of times per year. Canada is no longer a world leader in production, with production having developed in Russia, Ukraine and Kazakhstan where freight costs are lower to European and Chinese end markets. Flax prices tend to remain low until after harvest, so farmers should be prepared to store grain until markets begin to move again at the end of this year and into the beginning of 2018. Drought conditions of 2017 have hit North Dakota flax production particularly hard, which may end up supporting Canadian flax prices. According to LeftField Commodities, “Even with exports and domestic use similar to last year, the potential exists for a sizable drop in ending stocks which would be supportive for the price outlook.” For more information on current market outlooks, visit https://archive.flaxcouncil.ca/wp-content/uploads/2017/07/Flax-Market-Snapshot-July-4th-2017.pdf

When thinking about long-term storage of flax, producers should consider:

-

Retesting seed moisture to ensure flaxseed is in the recommended 8.5% for long-term storage.

-

Producers should also note that Malathion is not permitted for use in grain bins.